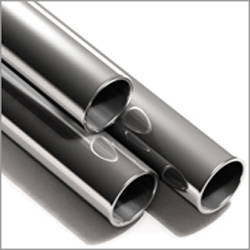

Metal Titanium Pipe

Price 1950 JPY (¥)/ Kilograms

MOQ : 1 Kilograms

Metal Titanium Pipe Specification

- Other Material

- Other

- Product Type

- Pipe

- Material

- Titanium

- Type

- Seamless / Welded

- Shape

- Round

- Standard

- Other

- Surface Treatment

- Other

- Diameter

- 1/2 inch to 12 inch Inch (in)

- Length

- Up to 6000 mm Millimeter (mm)

- Wall Thickness

- 0.5 mm to 20 mm Micrometers (um)

- Grade

- GR2 / GR5

- Density

- 4.51 Gram per cubic centimeter(g/cm3)

- Color

- Silver Grey

- End Finish

- Plain End / Beveled End

- Tensile Strength

- Minimum 355 MPa (for GR2)

- Elongation

- 20% (for GR2)

- Operating Temperature

- Up to 400C continuous

- Packaging

- Wooden Cases or as required

- Export Markets

- Global

- Pressure Rating

- High Pressure

- Hardness

- 160 HB (for GR2)

- Corrosion Resistance

- Excellent against acids, chlorides, and seawater

- Melting Point

- Approximately 1668C

Metal Titanium Pipe Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 10 Days

About Metal Titanium Pipe

Purchase the inestimable Titanium Pipe, an exceptional addition for industries demanding unsurpassed strength and corrosion resistance. Sought-after across global markets, this scarce yet triumphant material delivers substantial savings over its lifespan. Manufactured per ASTM B861/B338, it boasts a minimum tensile strength of 355 MPa (GR2), withstands high pressures, and operates consistently at temperatures up to 400C. Its excellent resistance to acids, chlorides, and seawater ensures reliable performance in chemical processing, aerospace, marine, and industrial settings. Available in seamless or welded forms, with polished or annealed finishes, each pipe exemplifies superior quality and resilience.

Versatile Applications and Usage of Titanium Pipe

Titanium Pipe is predominantly used in industrial, chemical processing, aerospace, and marine sectors due to its remarkable strength, corrosion resistance, and durability. It is installed as a crucial conduit for transporting gases and liquids under high pressure or corrosive environments. With its adaptable round shape and polished or annealed surface, the pipe serves as an integral component in pipelines, heat exchangers, and specialized machinery, ensuring efficient and safe operations in challenging conditions.

Sample Availability, Payment Terms, and Certification Process

Titanium Pipe samples are available for your evaluation before full purchase. We ensure a straightforward handover process, prompt supply, and competitive asking prices to support your requirements. Payment terms are flexible, catering to both domestic and international transactions. Each shipment is backed by certifications, guaranteeing authenticity and conformity to global standards. Our commitment ensures a seamless experience from inquiry to final delivery, promoting trust and satisfaction for businesses worldwide.

Versatile Applications and Usage of Titanium Pipe

Titanium Pipe is predominantly used in industrial, chemical processing, aerospace, and marine sectors due to its remarkable strength, corrosion resistance, and durability. It is installed as a crucial conduit for transporting gases and liquids under high pressure or corrosive environments. With its adaptable round shape and polished or annealed surface, the pipe serves as an integral component in pipelines, heat exchangers, and specialized machinery, ensuring efficient and safe operations in challenging conditions.

Sample Availability, Payment Terms, and Certification Process

Titanium Pipe samples are available for your evaluation before full purchase. We ensure a straightforward handover process, prompt supply, and competitive asking prices to support your requirements. Payment terms are flexible, catering to both domestic and international transactions. Each shipment is backed by certifications, guaranteeing authenticity and conformity to global standards. Our commitment ensures a seamless experience from inquiry to final delivery, promoting trust and satisfaction for businesses worldwide.

FAQs of Titanium Pipe:

Q: How does the Titanium Pipe benefit industries such as aerospace and chemical processing?

A: Titanium Pipe offers exceptional strength, high corrosion resistance, and durability, making it ideal for aerospace and chemical processing applications where safety, reliability, and longevity are required in demanding environments.Q: What is the recommended process for installing Titanium Pipe in an industrial setting?

A: Installation typically involves precision cutting, welding or mechanical joining, and rigorous quality checks to ensure secure, leak-free joints that withstand high pressure and corrosive conditions. Expert handling is essential to maximize its inestimable advantages.Q: When can samples of Titanium Pipe be handed over for evaluation?

A: Samples are usually available upon request and can be supplied quickly for evaluation, subject to the required specifications and current stock levels.Q: Where does the Titanium Pipe demonstrate its optimal performance?

A: This pipe performs optimally in environments exposed to acids, chlorides, and seawater, such as marine engineering, chemical plants, and aerospace systems requiring robust resistance and high pressure endurance.Q: What certifications accompany the supply of Titanium Pipe?

A: Every supply of Titanium Pipe is accompanied by conformity certifications that affirm adherence to ASTM B861/B338 standards, and other relevant international norms, ensuring quality and authenticity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Titanium Category

Heavy Metal Titanium Pipes

Price 1200 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Product Type : Other, Pipe

Color : Metallic Grey

Material : Titanium

Shape : Round

Titanium tank

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Titanium tank

Color : Silver

Material : Titanium

Shape : Round

Titanium Fastener

Minimum Order Quantity : 10 Kilograms

Product Type : Other, Titanium Fastener

Color : Silver

Material : Titanium

Titanium Coils

Minimum Order Quantity : 10 Kilograms

Product Type : Other, Titanium Coils

Color : Silver

Material : Titanium

Shape : Rectangular

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free