नितिनà¥à¤² à¤à¥à¤¯à¥à¤¬à¥à¤¸

Price 1000 आईएनआर/ टुकड़ा

नितिनà¥à¤² à¤à¥à¤¯à¥à¤¬à¥à¤¸ Specification

- तापमान

- Activation Temperature: 20°C to 40°C

- कोर की संख्या

- Single (Tube) Structure

- प्रॉडक्ट टाइप

- Nitinol Tubes

- मटेरियल

- Nickel Titanium (Nitinol) Alloy

- फंक्शन

- Shape Memory and Superelastic Applications

- उपयोग

- Medical Devices, Stents, Catheters, Actuators, Surgical Instruments

- लम्बाई

- Customizable, typically 50 mm to 1000 mm

- साइज

- Standard and Custom Sizes Available

- रंग

- Metallic Silver

- व्यास

- 0.2 mm to 10 mm (Customizable)

- एप्लीकेशन

- Biomedical Engineering, Robotics, Aerospace, Automotive, Electronics

- Corrosion Resistance

- Excellent

- Customization

- Dimensions, Alloy Composition, and Finishing as required

- Density

- Approx. 6.45 g/cm³

- Fatigue Life

- Highly durable, millions of cycles

- Melting Point

- Around 1310°C

- Wall Thickness

- 0.05 mm to 1.0 mm (Customizable)

- Shape Memory Effect

- Returns to predetermined shape on heating

- Biocompatibility

- Certified for Medical Use

- Surface Finish

- Polished, Sandblasted, Oxide-treated, or Custom

- Superelasticity

- High recoverable strain up to 8%

- Delivery Form

- Seamless Tube

- Hardness

- Rockwell C 15 - 45

नितिनà¥à¤² à¤à¥à¤¯à¥à¤¬à¥à¤¸ Trade Information

- Minimum Order Quantity

- 10 टुकड़ाs

- आपूर्ति की क्षमता

- 10 प्रति सप्ताह

- डिलीवरी का समय

- 10 दिन

About नितिनà¥à¤² à¤à¥à¤¯à¥à¤¬à¥à¤¸

Utilization and Features of Nitinol Tubes

Nitinol Tubes are employed by leading manufacturers in biomedical engineering, robotics, aerospace, electronics, and automotive sectors. Their unrivaled material features-shape memory, superelasticity, and biocompatibility-make them the preferred choice for medical implants, stents, and surgical instruments. In plant applications, these seamless tubes offer extended fatigue life and corrosion resistance, ensuring long-term reliability in high-performance environments across many industries.

Sample Policy, Domestic Market & Packaging

Nitinol Tubes samples are offered at a list price with options for exchange, subject to availability. We serve the entire domestic market in India, shipping products nationwide for prompt delivery. Packaging details include secure, export-quality boxes that preserve the tubes' integrity throughout transit, whether shipped as single pieces or in bulk quantities. Customers may request tailored packaging solutions for specialized needs.

FAQ's of Nitinol Tubes:

Q: How does the shape memory effect work in Nitinol Tubes?

A: Nitinol Tubes return to their original, pre-set shape when heated to the activation temperature, typically between 20C to 40C, thanks to the alloy's shape memory effect.Q: What customization options are available for size and finishes?

A: Customers can specify custom dimensions, alloy composition, surface finishes (polished, sandblasted, oxide-treated, or custom), wall thicknesses, and lengths to best suit their technical requirements.Q: Where are Nitinol Tubes primarily used?

A: These tubes are widely utilized in medical devices, surgical instruments, actuators, stents, catheters, and across robotics, automotive, aerospace, and electronics industries.Q: What benefits do Nitinol Tubes offer for medical applications?

A: With certified biocompatibility, excellent fatigue life, corrosion resistance, and high superelasticity, Nitinol Tubes enhance the durability and effectiveness of medical implants and devices.Q: What is the process for sample delivery and pricing?

A: Samples are shipped at a list price, with options for exchange based on availability. Packaging is handled to ensure safe delivery, and special requests can be accommodated for domestic and export markets.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in नितिनोल Category

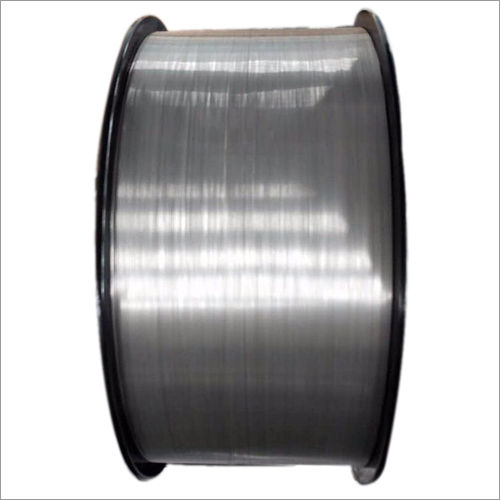

नितिनोल वायर

मूल्य या मूल्य सीमा : आईएनआर

उपयोग : Actuators, Medical Devices, Robotics, Industrial Applications

मटेरियल : NickelTitanium Alloy (Nitinol)

न्यूनतम आदेश मात्रा : 100

माप की इकाई : ग्राम/ग्राम

प्रॉडक्ट टाइप : Nitinol Wire

Ni50Ti50 नितिनोल

मूल्य या मूल्य सीमा : आईएनआर

उपयोग : Shape memory and superelasticity

मटेरियल : Ni50Ti50 Nitinol

न्यूनतम आदेश मात्रा : 1

माप की इकाई : किलोग्राम/किलोग्राम

प्रॉडक्ट टाइप : Wire

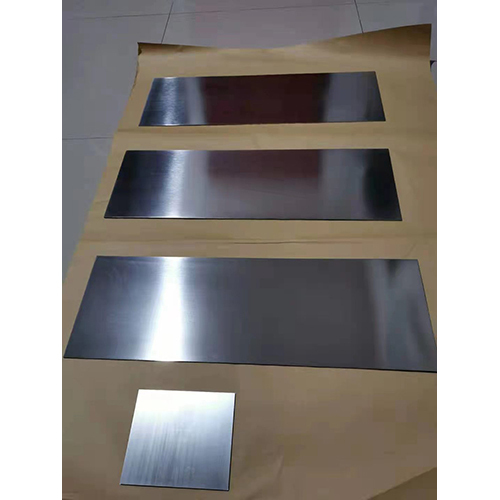

नितिनोल शीट

मूल्य या मूल्य सीमा : आईएनआर

उपयोग : औद्योगिक

मटेरियल : नितिनोल

न्यूनतम आदेश मात्रा : 1

माप की इकाई : किलोग्राम/किलोग्राम

प्रॉडक्ट टाइप : नितिनोल शीट

नितिनोल शीट

मूल्य या मूल्य सीमा : आईएनआर

उपयोग : औद्योगिक

मटेरियल : नितिनोल

न्यूनतम आदेश मात्रा : 10

माप की इकाई : किलोग्राम/किलोग्राम

प्रॉडक्ट टाइप : नितिनोल शीट

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें